Being the heart of mechanical equipment, the building of highly efficient and reliable electric motors is key to the successful operation of different industrial fields.

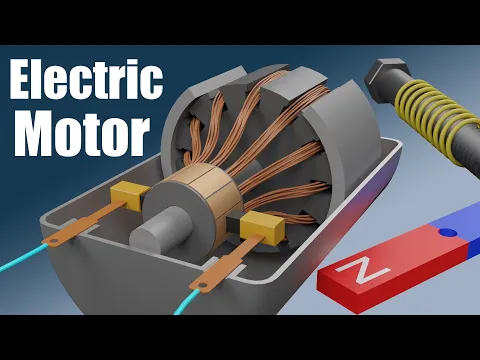

An electric motor is a machine that converts electrical energy into mechanical energy, powering various different industrial machinery and tools. With more and more industrial manufacturers relying on specialized electric motor manufacturers, it is now a highly profitable business. Back in 2017, the size of the global electric motors market was over $96,000.00 million, with an estimate to raise it past the $100,000.00 million mark by 2025. However, this surge in popularity for them is not only good for its manufacturers but also greatly beneficial for the different industries that rely on them.

Thanks to the ever-increasing market shares, electric motors are now available in various different types, with its application ranging in a great variety of industrial machinery and equipment. The availability of specifically designed motors such as the one that you can find visiting omemotors.com is a big help too, as they tend to be more innovative and efficient for their dedicated efforts in improving the performance level.

There exist several types of electric motors, which can be classified on the basis of various characteristics, such as their internal construction, the power source type, their applications or the type of motion output. As for the source type, electric motors can be powered by alternating current (AC) sources (some examples can be power grids, electrical generators, or inverters), or by direct current (DC) sources (including rectifiers, batteries or motor vehicles). Other electric motor typologies are:

- Brushed or brushless (sometimes called ECM, that stands for Electronically Commutated Motor)

- Single-phase, two-phase or three-phase (according to the number of conductors)

- Air-cooled or liquid-cooled (whether their cooling system is based on air or on a cooling liquid).

We can also observe extremely different sizes of electric motors, depending on their application: they vary from really small motors (used for electric watches), to very large ones, used for activities such as ship propulsion, pipeline compression, or pumped-storage applications; this kind of electric motors is able to reach ratings of 100 megawatts.

Electric Motors with Standard Application

There are quite a few different types of standard electric motors which are regulated by the International Electrotechnical Commission (IEC) to ensure maximum safety and efficiency. These standard motors are usually low-voltage motors (operating at voltages less than 1000 V, and producing a maximum power of 1000kW), with its application that includes cement industries, sugar refineries, water purification systems, food processing units, produce machinery for the processing of wood, plastic, paper, light alloys, glass, iron, or marble, air treatment plants, power plants, etc.

They are the most traditional types of motors, which are defined by their higher safety assurance, highly efficient performance, lower electricity consumption, and enhanced reliability; plus, they are characterized by their maximum versatility and adaptability to the sector of use. The premium range of standard OME Electric Motors is also great to comply with the mandatory regulations of the European Union.

Advanced Electric Motors for Specific Use

There is also a great variety of specialized electric motors that are manufactured with specific industries in mind. An example can be the industries that operate in so-called “hazardous locations”, that is places where it exists the chance to have fire or explosion hazards, due to flammable gases, flammable or combustible liquid–produced vapors, combustible dusts, or ignitable fibers and particles that may be present in the air in a quantity sufficient to produce ignitable or explosive mixtures. The petrochemical industries, for example, are highly explosive and require electric motors that are the safest.

That is why there are some explosion-proof electric motors specifically designed to withstand the rigor of such industries, and that are ATEX certified, which means that they respect the directives from the European Commission related to the phenomenon of explosive atmosphere. The steel, glass, and iron mills, on the other hand, operates in a very heated environment, requiring them to utilize high voltage motors (designed to be light and compact, with low noise and vibrations) or motors with a self-cooling system (the simplest one being an axial fan attached to the rotor, that spins together with the motor in order to provide increased airflow to its internal and external part). Another key factor is the reliability of such motors, as they would be running continuously to maintain a seamless production system.

Compact Electric Motors for Industrial Equipment

In addition to the types of machinery directly used in production, there is also some other equipment used by the industries to perform specific tasks. It includes things like conveyor systems in food processing industries, compressors, and fans, industrial ventilators, turbines and pumps in water plants, etc. Conveyor belts, for example, are a category of machinery that can be powered by this type of electric motors: they have the purpose to produce the movement of a product at a constantly controlled speed, which is particularly important for industries such as steel plants.

The electric motors used in this equipment need to be designed in such a way that it makes less noise and fewer vibrations, in addition to producing high torques. They also need to be able to operate in a hazardous environment, making the production and development of specialized ad hoc OME Electric Motors a highly useful one.